Side Cutter

- Especially for use in electronics manufacturing

- Cutting edge hardness 54-56 HRC

- Precision cutting edge for the finest wires

- With 21° angled cutting edges

- Tight-fit joint movement

- With lap-joint and opening spring

- Ergonomically multi-component safety handle for better handling

- Easy handling because of little weight

- Made of finely punched carbon-steel C70, hardened without distortion

Use tools for indicated purposes only.

Before using the cutting tools please wear body protection such as safety mask, safety glasses and hand protection.

Beware of wire ends flying off!

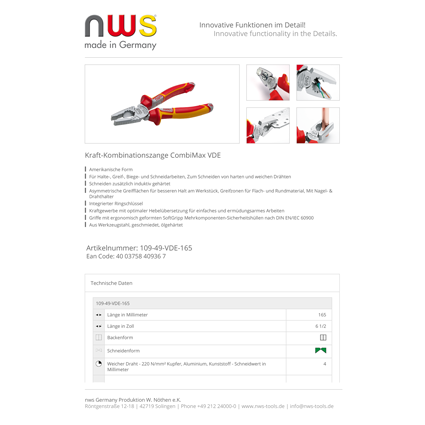

ProfileLine

The pliers & cutters in the 19 series, ProfileLine are fine blanked from precision carbon steel (C70), have excellent cutter geometry and have been hardened to 54 - 56° HRC to reduce warping and stresses. The polished cutting faces and the non-reflecting phosphated surfaces promote safe working and ensure a good view of the job. The spring-loaded opening mechanism and endstops in conjunction with the soft, hand-friendly 2-component handles ensure strain-free working.

Small charges can have considerable impact.

High-performance electronic components are to found in all our smart phones, industrial machinery and our washing machines at home. This makes every repair a job for the professionals. Even the slightest static build-up is enough to damage or destroy sensitive components. This is why professional service engineers rely on ESD tools by NWS. That way, they can be sure that their professional repair skills are matched by corresponding handling of the parts.

Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Pусский

Pусский