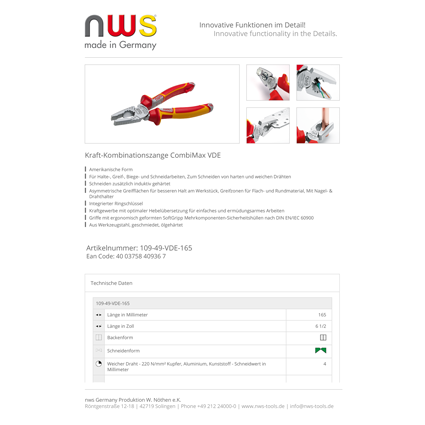

Angled Screwdriver 1000V

- For hexagon socket screws

- Especially for cable branch clamping rings

- Multi-layered insulation according to DIN EN/IEC 60900

- Made of chrome vanadium steel, forged, oil-hardened

- Base tool chromium-plated

| Article |

|

|

|

|

|

|

|

|||

|---|---|---|---|---|---|---|---|---|---|---|

| 2018-3-130 | 130 | 3 | DIN 7439 |

|

20 | 1 | 40 03758 20183 1 | |||

| 2018-4-120 | 120 | 4 | DIN 7439 |

|

25 | 1 | 40 03758 20184 8 | |||

| 2018-5-140 | 140 | 5 | DIN 7439 |

|

45 | 1 | 40 03758 20185 5 | |||

| 2018-6-140 | 140 | 6 | DIN 7439 |

|

60 | 1 | 40 03758 20186 2 | |||

| 2018-8-150 | 150 | 8 | DIN 7439 |

|

110 | 1 | 40 03758 20188 6 | |||

| 2018-10-220 | 220 | 10 | DIN 7439 |

|

230 | 1 | 40 03758 20180 0 | |||

| 2018-12-260 | 260 | 12 | DIN 7439 |

|

350 | 1 | 40 03758 20182 4 |

For working at or close to electrical parts please observe safety regulations for electrical works and additional national safety regulations.

Check that insulation is not damaged each time before using the tools. Do not use damaged tools anymore. Keep your safety tools clean and dry. Ensure that the workplace where you are working on live equipment is clean and tidy. Use protective clothing and safety equipment (eg. safety gloves, cover clothes and safety sleeves), especially when working in narrow areas.

Electrical work (worked carried out on electrical devices an systems) must be either conducted by a qualified electrician or supervised and checked by one.

Better safe than sorry.

Electricians put their faith in their tools daily. Electricity is always a potential hazard. Whether they are cutting cables to size, fitting socket outlets or configuring switch cabinets, they need tools they can rely on without fail. When an electrician picks up a set of VDE tools made by NWS, he or she is handling quality tools subjected to stringent testing for practical, hands-on applications in electrical jobs. This is, after all, what professional working, health & safety are all about.

Safety testing method according to IEC 60900

• Visual check and check of measurements: single check of the lettering on the basis tool as well as on the insulation.

• Check of resistance under hot and cold conditions: under normal temperatures of the surroundings (23° C) as well as under low temperatures (-25° C) on three different positions easy to hurt.

• Single voltage check: check of the electrical insulating characteristics by putting on a 10 KV voltage in a water bath for three minutes and measuring the deflecting electricity.

• Pressure check - check of puncture: storage of tools in a warming box for 2 hours at the temperature of 70° C putting on a 5 KV Voltage for three minutes and raising a power of 20 N on the insulation.

• Check of the adhesive power of the insulation: storage of tools in a warming box for 168 h at a temperature of 70° C raising a power of 500 N for three minutes on the area between the conductive part and the insulation.

• Check of fire risk: raising a flame on the insulation for 10 seconds.

Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Pусский

Pусский