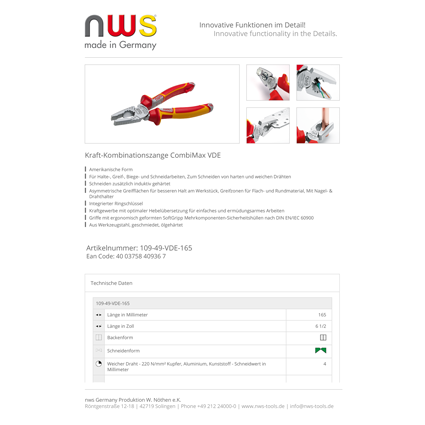

Crimping Lever Pliers for End-Sleeves

- For processing end-sleeves with and without insulation collars according to DIN 46228

- For establishing solderless, electrical connections according to DIN

- High precision due to special profile geometry with profile identification

- With optimum leverage for easy and effortless work

- Integrated, releasable restraint lock for controlled pressing in one operation

| Article |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 583-210 | 210 | 8 1/4 |

|

0,5 - 6 | 22 - 10 | 5 | 0,5 - 0,75 | 1,0 - 1,5 | 2,5 | 4,0 | 6,0 |

|

400 | 1 | 40 03758 58300 5 | |||||

| 583-210-SB | 210 | 8 1/4 |

|

0,5 - 6 | 22 - 10 | 5 | 0,5 - 0,75 | 1,0 - 1,5 | 2,5 | 4,0 | 6,0 |

|

400 | 260 | 75 | 20 | 410 | 1 | 40 03758 68300 2 | |

| 584-210 | 210 | 8 1/4 |

|

6 - 16 | 12 - 4 | 3 | 6,0 | 10,0 | 16,0 |

|

405 | 1 | 40 03758 58400 2 | |||||||

| 584-210-SB | 210 | 8 1/4 |

|

6 - 16 | 12 - 4 | 3 | 6,0 | 10,0 | 16,0 |

|

415 | 260 | 75 | 20 | 10 | 1 | 40 03758 68400 9 |

Crimping tools

Once again, "Made in Germany" is a key feature: the handles are plastic dipped and the hand-forged plier heads are made of oil-hardened titanium-finish steel and meet the high demands that we and our customers expect of our products. They are optimised for solderless connections in compliance with DIN standards, which is achieved by the specially designed profile geometry.

Connecting to the future

Solar energy is a clean alternative source of electricity. To make sure it is also a safe source, junction box and switch cabinet wiring has to be properly stripped, crimped and connected up. Using NWS wire stripping and crimping tools, electricians can handle wires and cables in line with all the applicable regulations and down to the millimetre. In this way, whether private houses, factory roofs or photovoltaic installations, they all become clean and safe players in the transition to renewable energy sources.

Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Pусский

Pусский